From the manufacturer’s point of view

A chandelier is born from an idea, an intuition, a particular request from a customer, from market signals, from a fair, from the need to exploit a new technology. It can also be created by revitalizing the so-called mature models.

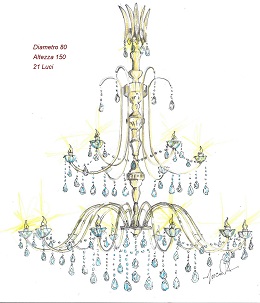

The most delicate phase is the design of the new model by a designer and by the technical office of the manufacturer. Together, in fact, combining technical skills and creative point of view, it is possible to evaluate the feasibility of the project starting from the sketches to realize the technical drawing. Various elements will be considered for the choice of the most suitable components, the materials to be used, the colors; the technical constraints will be highlighted by making changes to the initial idea if necessary. After defining the sketch, we move on to the realization of the prototype and test. The stage is very delicate and requires great professionalism and expertise. In addition to the materials, assembly procedures are defined, a check is carried out on the possible presence of mechanical defects, on product safety, light diffusion and product aesthetics.

The last aspect to be carefully considered is the selling price of the product. The desirable goal in the diffusion of a unique and artisanal product is to offer a quality product, with special regard to Made in Italy, at a price considered appropriate by the customer according to his expectations.

Start of production.

At the end of the implementation phase of the first prototype, we get to that of the introduction of the new model in the production process of the company. In this phase, all the considerations that have occurred on the feasibility of the prototype are explained, and the technical implementation is checked, considering also aspects useful to the diffusion of the product, such as the design of the most suitable packaging for the product to travel without being damaged.

The structure of the chandelier, especially the classic one, can be chrome iron (or better to say metal), brass and aluminum. Depending on the customer’s choices, the structure may have different finishes that can involve the use of gold, brass, chrome, nickel, silver, golden bronze and antiques.

Chrome iron is a type of iron particularly used in the field of lighting and furniture for its characteristics that make it suitable for the galvanic treatments of decoration (golden, chrome, nickel, etc.).

Brass is a stainless alloy that is mainly used for its “versatility”. The so-called brass castings best represent this feature, ensuring the creation of almost unique pieces that make the chandelier inimitable.

The anodized aluminium is a type of alloy that has two main characteristics: it is extremely flexible and very durable. The type of processing (the grinding)gives the product a particular design and shine.

The chrome iron and brass, after the various processes (curve, welding, folding, ect) follow the galvanic process to be finished according to the taste of the customer and the needs of the production of the company. With this process the chandelier is “embellished” and becomes golden, chrome, nickel, bronze. This process, in addition to “coating” the chandelier, makes it particularly resistant to the processes of oxidation and corrosion. In fact, if the galvanic process and metal used are of high quality, it is almost impossible that the finish can be ruined by the time.

Materials such as Murano’s crystal, porcelain and glass are historically used to embellish and decorate the chandelier, often in combination with each other.

The crystal, in all its particular shapes, transparent or colorful, Scholer and Asfour, makes the chandelier bright and shiny.

The porcelain, decorated with wise and expert hands in an accurate way, guarantees the high quality, according to a tradition consolidated over time.

Murano glass, the artistic glass par excellence, has always offered the opportunity to admire small and great masterpieces of glass masters.